How is asphalt produced and what potential does it have for our environment? We use asphalt for road surfaces, but also in structural engineering and hydraulic engineering. But rarely do we think about the environmental compatibility of the material. On closer inspection, however, the production of asphalt pavements offers unimagined potential for the environmental compatibility of human activities.

In this article, I therefore take a closer look at the production of asphalt, its processing and environmental impact, as well as the opportunities offered by the use of reclaimed asphalt.

- Asphalt production

- Reconditioning of old asphalt

- Use of old asphalt

- Environmental compatibility

- Closing words

This is how asphalt production works

For the production of asphalt in stationary, wheeled or transportable asphalt mixing plants₁, two different processes are basically used today. Continuous production describes a non-stop mixing process in continuous operation, in which the individual components of the asphalt are continuously added. This production method is particularly suitable for projects in which the mixing recipe is permanently identical. Discontinuous production, on the other hand, provides a more flexible mixing process. Here, the pre-weighed components of the asphalt are mixed in batches. It is more flexible because during the process it is possible to adjust the mixing recipe batch by batch and to achieve a higher result quality.

Discontinuous production is also the preferred process for asphalt production in Europe. In most cases, aggregates and bitumen are used as components in a thermal mixing process to produce asphalt. In rural regions with a poorly developed infrastructure, mobile equipment is preferred for this purpose. Urban areas tend to prefer the use of stationary mixing plants.₂

Basically, companies in the production of asphalt pursue the goal of delivery on time and according to requirements - and for this, factors of information, plant engineering, process safety, monitoring, expert personnel and process principle must all be taken into account.₃

Asphalt production in the mixing plant

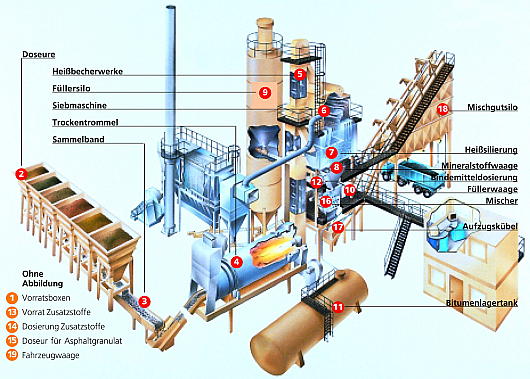

The practical production of asphalt in the mixing plant usually starts with the metered addition of sand, gravel, chippings or other mineral aggregates from meterable containers - the so-called batchers. A conveyor belt then transports the moist materials in the desired proportions to the so-called drying drum. There they are heated and dried. In the next step, the mixed materials are transported via hot bucket elevators to a higher level of the mixing plant, where they are then separated again into their individual components by a screening machine and stored sorted in the storage silo - the so-called hot silo. With the aid of a mineral scale, the granules can be removed from the silos in the subsequent step according to the desired weight and forwarded to the mixer.

In order to be able to add binder and filler to the mixer, both materials are taken in metered form from the storage tank and the filler silo by the binder metering system or the filler weigher. With the aid of a further batcher, reclaimed asphalt can now also be added as a secondary raw material in this phase of the production process, for example by milling or breaking up asphalt in layers that has already been used once and processing it into asphalt granules.

Once all the desired constituents have reached the mixer and have been mixed together there, the asphalt obtained is shipped via a mobile bucket to a mix silo, from where it can be loaded into transporters. The basic processes in a mixing drive are carried out from a control panel.₄

Environmental compatibility of asphalt production

Only minor emissions are generated during the delivery, storage and further processing of bitumen. In this respect, road construction companies and other asphalt processing companies are subject to strict health regulations, which they must comply with in order to protect their employees. In principle, however, bitumen does not count as a hazardous substance for the environment.

Nevertheless, the material offers opportunities for environmental protection - namely in the reuse of old asphalt. How this works and what else you need to know about it, I would like to explain to you now in the next few paragraphs.

Reconditioning of old asphalt

Since the binder bitumen is thermoplastic and the temperature-induced softening and hardening can be reversed, it is ideally suited for environmentally friendly processing and reuse.₅ In principle, new asphalt can be obtained from secondary raw materials such as reclaimed asphalt (e.g. from a dismantled asphalt road) by processing it into asphalt granulate in various processes. One possibility of reusing so-called reclaimed asphalt is to mill the asphalt surface course, asphalt binder course and asphalt base course in order to obtain small-particle milled asphalt and process it into asphalt granulate. By breaking it up into smaller slabs layer by layer, reclaimed asphalt can also be turned into so-called crushed asphalt, which can then also be further processed into asphalt granulate in a crushing process.₆

Once milled and broken asphalt has been extracted, this is usually done in the asphalt mixing plant, where the material is first stored and then broken up, sieved and added to the so-called mixer for the production of new asphalt.₇ The so-called grading curve diagram, from which the proportions of the different grain sizes of the construction material can be read, is decisive for the maximum amount of old asphalt to be added. The corresponding values are determined by sieving the soil samples with increasing reduction of the mesh size. After successful production, the asphalt can then be transported to the desired location and laid on site.₈

Use of old asphalt

The potential savings from reusing reclaimed asphalt production feedstocks are very large from both economic and environmental perspectives. Companies can benefit from economic advantages in the increased use of reclaimed asphalt, for example, since construction prices for road building are rising sharply and they could still maintain their competitiveness in the long term. Both the bitumen price index and the asphalt price index have continued to increase for years. In February 2019, raw material prices for road construction even increased by 7.5 percent year-on-year.₉ The global decline in worldwide oil reserves (bitumen reserves) and the fact that around 70 percent of these oil reserves are located in politically unstable countries₁₀ are among the reasons for the increasing prices on the world market and reveal further potential for savings.

In addition to the fact that natural resources can be conserved by using reclaimed asphalt, there is a further advantage from an ecological point of view, above all in the reduction and elimination of waste. In asphalt production, there is also enormous potential for saving energy in the asphalt mixing plant, for example through the use of residual heat or shorter transport routes.₁₁

The annual evaluation of asphalt production in Germany carried out by the German Asphalt Association (DAV) e.V. shows that of around 13 million tons of old asphalt mined, around 10.9 million tons could be reused - this corresponds to a recycling rate of around 84 percent - this figure is down on previous years. Furthermore, the evaluation shows that of the total of about 42 million tons of asphalt produced in 2017, about 26 percent came from reuse. This figure has continued to rise since 2011. This trend gives hope that the great savings potential in asphalt production will be exploited even more efficiently in the future.₁₂

Use old asphalt to conserve natural resources

In the sense of the Urban Minings and the protection of our planet, we should rely more on alt-asphalt in the future. I hope that I can help you with this article from the Knowledge blog was able to get a clearer picture of asphalt production as well as its opportunities for environmental protection.

Do you have any questions or suggestions? Then, as always, feel free to write a comment.

Stay curious,

PS.: Feel free to look around a little bit in the Mobility Blog um. Learn, for example, how sustainable e-scooters actually are.

References:

₁ BENNINGHOVEN: Asphalt production - It's all in the mix, available at https://t1p.de/n2e7. [01.06.2020].

₂ WIRTGEN GROUP: Asphalt production - it's all in the mix, available at https://t1p.de/zzmo. [01.06.2020].

₃,₄,₅, Deutscher Asphaltverband (DAV) e.V.: Asphalt herstellen und liefern, available at https://t1p.de/nzyn. [01.06.2020].

₆ C. Meurer: Wohin mit dem Ausbauasphalt - Recycling aber richtig, available at https://t1p.de/svm9. [01.06.2020].

₇,₁₀ R. Mansfeld (2012): Reusing asphalt - Asphalt granulate cycle (ideal), available at https://t1p.de/8oyw. [01.06.2020].

₈ BENNINGHOVEN: Recycling Management, available at https://t1p.de/ytrc. [01.06.2020].

₉ Statista GmbH: Development of construction prices in Germany from August 2016 to August 2019 (as of October 2019), available at https://t1p.de/npmc. [01.06.2020].

₁₁ ECA Concept GmbH: High energy saving potential in asphalt mixing plant, available at https://t1p.de/t2sg [01.06.2020].

₁₂ Deutscher Asphaltverband (DAV) e.V.: Asphalt production in Germany (2018), available at https://t1p.de/tyzl. [01.06.2020].

I find the use of old asphalt for further use very good. So you can really not only save costs, but also help the environment. I also like the fact that the same asphalt mixing plant can be used for production and no additional equipment is needed. It will definitely be the technology of the future.

Thank you for this interesting article on pavement production and the environmental potential of waste asphalt. My uncle works in an asphalt mixing plant company and also told me about the possibility of reusing old asphalt for environmental protection. It's good to know that there is also enormous potential for saving energy consumption in asphalt production by using residual heat or by shortening transport routes.

Comments are closed.